Megafoam Inc. is a full service manufacturer of moulded foam products and protective packaging to the Aerospace, Automotive, Electronics, Defence and Security industries. Megafoam’s expertise in program management from concept to production ensures cost effective solutions for your most critical applications.

Megafoam Technology & Capabilities

Design Capabilities & Process

Establish Design Requirements

Megafoam establishes design requirements with customer engineering and/or Megafoam best practices for sealing against wind noise and injection molded part attachment scheme

Perform Team Feasibilities

Megafoam performs the team feasibility process, checking the part, tooling, fit and function

Apply OEM Best Practice

Applying OEM recognized best practices to develop part design Drawing Specifications

In-House Part Design

Get in-house part design and/or design support, utilizing NX10 (with Mold Flow), Catia, Solidworks, AutoCad, and more

In-House Mold Design

Megafoam offers multiple in-house mold design options; injection molding, thermal compressions molds, rapid prototyping capabilities, and more

Design Verification

Compare to model and assemble customer parts, laser thickness measurement, optical comparator measurement, and material testing and validation

Design Validation

Megafoam attends and supports OEM validation, including vehicle installation, fit and function, pressurization, powder and chalk tests, wind tunnel tests, plant trials and more

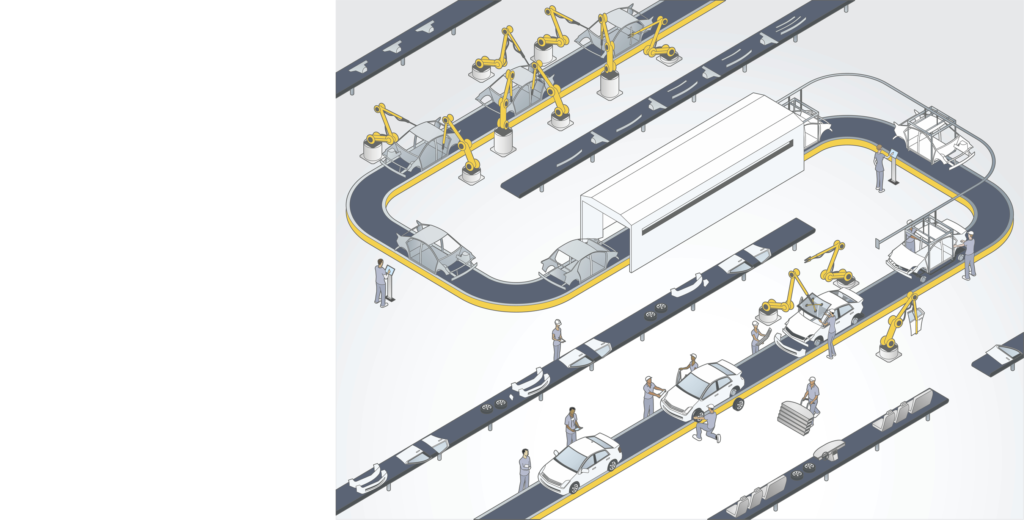

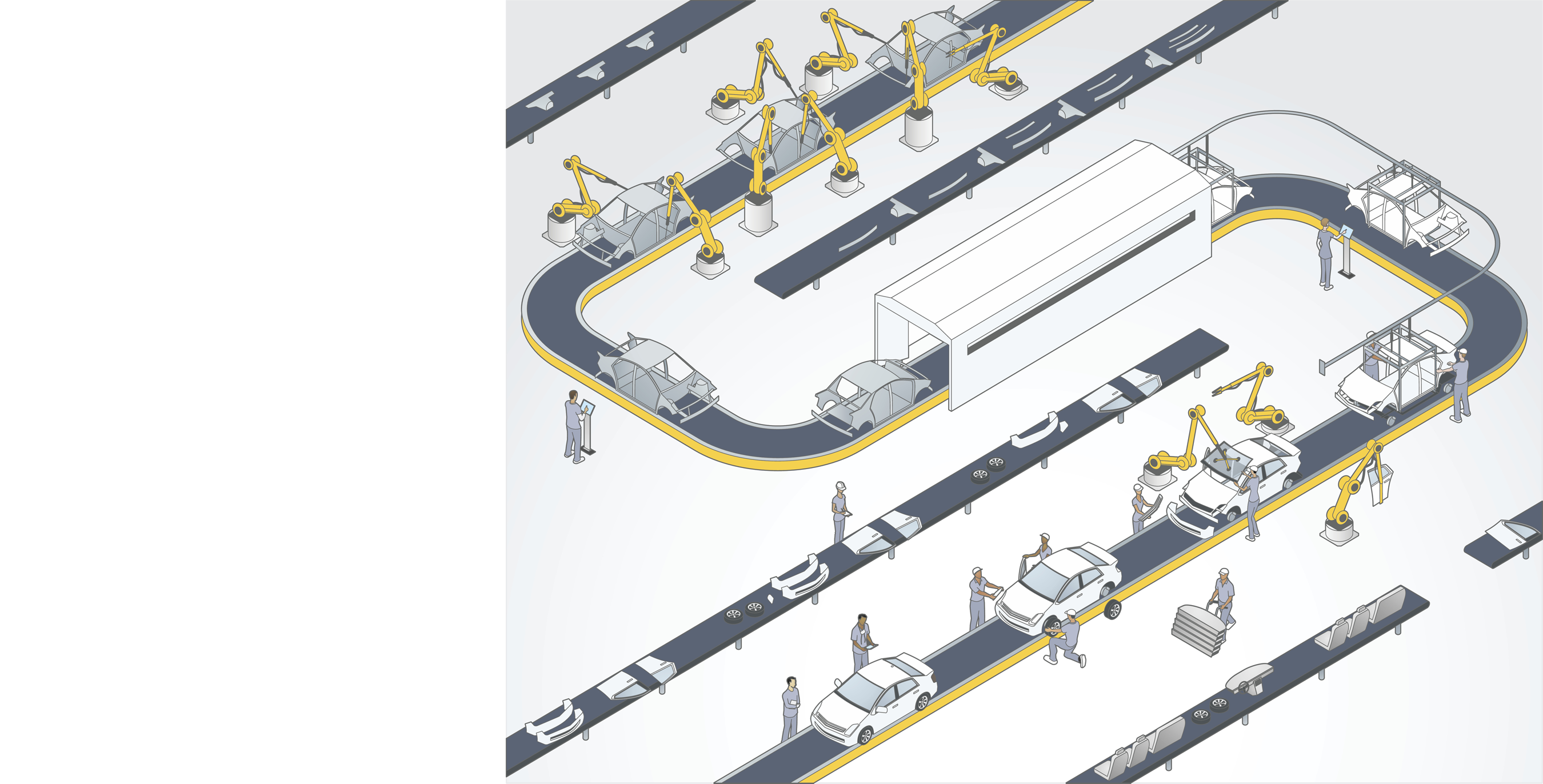

Manufacturing Capabilities

Injection Molding & Assembly

Thermal Compression

5-Axis Waterjet Cutting

Splitting and Slitting

Die-Cut

Bonded Assemblies

Contact Megafoam Inc Today

Call (905) 264-9166 or